R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer

Set Lowest Price Alert

×

Notify me, when price drops

Set Alert for Product: QIDI X-PLUS3 3D Printers Fully Upgrade 600mm/s Industrial Grade High-Speed 3D Printing with 65℃ Independent Heated Chamber and CoreXY Structure & Klipper Support Auto Leveling 280x280x270mm Print Size - $689.99

Last Amazon price update was: January 9, 2025 23:16

×

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on Amazon.com (Amazon.in, Amazon.co.uk, Amazon.de, etc) at the time of purchase will apply to the purchase of this product.

R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer

$689.99

R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer Price comparison

R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer Price History

Price History for QIDI X-PLUS3 3D Printers Fully Upgrade 600mm/s Industrial Grade High-Speed 3D Printing with 65℃...

Statistics

| Current Price | $689.99 | January 9, 2025 |

| Highest Price | $689.99 | August 6, 2024 |

| Lowest Price | $689.99 | August 6, 2024 |

Since August 6, 2024

Last price changes

| $689.99 | August 6, 2024 |

R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer Description

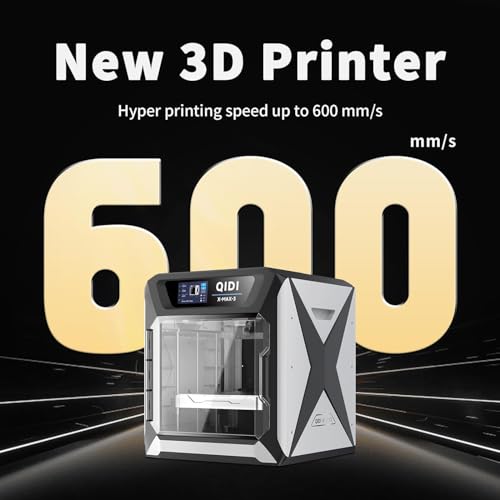

- 【Large Format & High-speed 3d printer】 Upgrade maximum speed 600mm/s and 20000mm/s² acceleration, 325*325*315mm printing size. Fully assembled and auto leveling, Featuring Klipper firmware and CoreXY structure, the desktop 3d printers is out of box for using. Perfect for professionals and beginners. The QIDI X-MAX3 3D printer is one of the best fast and large 3d machine around.

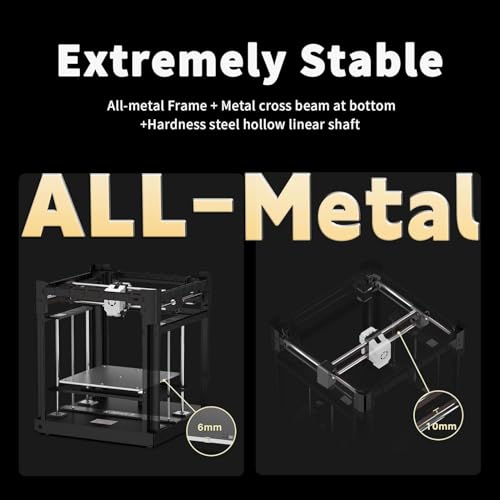

- 【Stable and long term usage】X-Max3 have Ultra-stable all-metal frame, 6mm thickness aluminum heatbed plate, 10mm width belt, ⌀10mm hardened hollow steel linear shafts, ensures smooth and stable printing, and no need for frequent maintenance. More reliable 3d printer accessories, less printing worries.

- 【High Performance Materials】QIDI High performance filaments can perfectly print in X max3, such as PA12-CF/PET-CF/PAHT-CF/ABS-GF etc. You can explore various printing options and achieve exceptional results. Meanwhile,direct drive extruder can easy print standard materials(PLA,ABS,ASA,PETG,TPU) or experiment with specialty filament(PC,PA,Carbon fiber,GF), this printer provides versatility and flexibility to accommodate your printing needs.

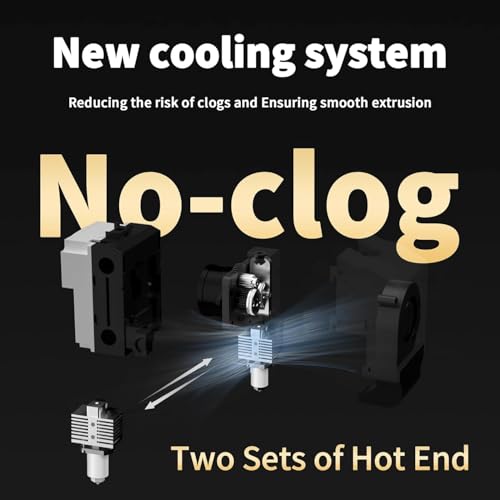

- 【Fast and High-Precision】 The enclosed chamber heating system and dual cooling fans, is designed to deliver exceptional printing quality and capture fine details with precision. With Input shaping and Pressure advance, whether you’re working on intricate designs, small-scale prototypes,lab modeling or artistic creations, this printer always guarantees outstanding print results.

- 【About R QIDI TECHNOLOGY MAX3 3D Printer】Open source Klipper firmware and QIDIslicer software for easy remote control and expansion of other custom functions such as cameras. X-MAX3 provide free one-year warranty, lifetime technical assistance from QIDI Tech. Professional after-sale service team will help customers solve the problem within 12 hours.

R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer Specification

Specification: R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer

|

R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer Reviews (4)

4 reviews for R QIDI TECHNOLOGY QIDI MAX3 High-Speed Large 3D Printer

Show all

Most Helpful

Highest Rating

Lowest Rating

Only logged in customers who have purchased this product may leave a review.

Fern –

I ordered this printer to help me test and make finished mechanical keyboard cases as well as print some toys for the kids. My primary focus was something large enough that I wouldn’t have to model parts smaller than needed. There aren’t many printers available that can both suit that need and feel reliable.

Once the printer has been tuned, it works incredibly well. The on-screen setup guides you fairly well, and the very close to stock Klipper means everything remains rather intuitive. Print quality is stellar, and as of firmware update v4.3.13 it has become clear that improvements have been made to filament retraction as banding that used to appear on benchy’s have smoothed significantly. The profiles in Orca Slicer work perfectly. I primarily use PLA+ from Overture, eSun, and IIID Max on this machine and they all work exactly as intended.

There has also been an improvement to my bed variance (down from 0.45mm to 0.30mm); that is likely attributed to the Z-offset now starting from 0 rather than the value I set which obviously needed improving. Case in point: I damaged my PEI sheet by failing to level my bed after the stored Z-offset value was set higher than the highest bound. Between a combination of reading the website material and reaching out to Qidi support for my specific model, I was able to get my printer working again and was immediately given tracking for my replacement PEI sheet.

The point that I want to get across most in this review isn’t that it’s large or fast. That can all be read above in the promo material in this product listing. The biggest point isn’t even the amazing support I received from Olivia who walked me through what I should be looking for, what I needed to have done to make sure that the printer was fixed, and what I needed to do to make sure the issue wouldn’t happen again.

The biggest selling point to this printer is the active development. This printer is still receiving updates that significantly improves print results and curtail issues. The commitment to this product reassures me that I do not have to regret my purchase ever.

Yes- there are some design issues that I would have liked to see differently like the spool holder being in the rear of this heavy colossal unit of a machine. I just hooked up my filament dryer to it instead, so it has become a non-issue (and before anyone thinks that shouldn’t be a solution should also learn that a filament dryer basically a necessity in FDM printing and should have one on hand in case you want to do the same thing as me). There are some cavities inside the enclosure that are unreachable with human hands and I’m pretty sure I’m building up bits of PLA in there. I’ll vacuum that eventually. There’s no AMS option, but that’s just me nitpicking.

The fact of the matter is no printer is perfect, but this one does a better job than most anything out there when you consider the price.

If you want a >256mm^3 format Core XY printer with high reliability, responsive support, and active firmware development, the value is qualitatively unbeatable. I am very happy with my purchase and with the prints my kids and I have been able to enjoy with this printer.

Fern –

I bought this on a whim, a friend said he wanted this printer and it sat open in a tab on my computer for a few months before I decided to go for it. I’ve wanted one of these for years but wanted to wait for a while for the tech/hardware to get better. I didn’t want to get something cheap and disposable and from what research I did this seemed like a great deal for the price.

If you do get into this hobby, familiarize yourself with SSH clients and commands because you will be connecting to the printer for either maintenance or installing new software to use. It had been about a decade since I’ve done any coding so it took me a while to catch up and remember commands for SSH navigation. Luckily g.code and config files are pretty straightforward and the macros and commands aren’t too hard to figure out if you have any familiarity with coding logic.

The company is great and actually cares about their customers, their feedback, and experience. My first time contacting them was the night before my wife went into labor with our first child and I was running on about 3 hours of sleep over a 48h period and I was NOT very nice in my first communications. Annie took it in stride and is still emailing me to check in and answer questions I have as I move on to more difficult materials and more complex software questions. I’ve had parts break and they have sent me completely free replacements which has been very helpful as I am still new to this and am trying to learn as I go. And with a 1 month old at home money is definitely tighter than it was.

I use QIDI filaments and they work great. I’ve used a few other brands but had issues with quality/adhesion so I stick to their filaments since they make the printer. I got the package and within an hour I was printing PLA items while I went back to work to finish the day. Their included slicer is a great beginner tool and I still use it from time to time but have been experimenting with OrcaSlicer for calibration tests that auto generate, additional settings to tinker with, and being able to slice and directly send my print via WiFi. They are constantly updating their slicer/firmware using customer feedback so I don’t seem them lagging too far behind as they grow. I had the printer inside and it was honestly great since I live in a cold, humid area but since I started printing volatile materials such as ABS, ASA, and PETG I moved it to the detached garage. Not the worst thing since all of my tools are in there and they appreciate the heat and the printer helps drive out humidity.

The dry box on the printer is a great idea and I’ve ordered more silica packets since the garage usually sits between 45-65% humidity regardless of the time of year. I typically print one spool at a time since an open roll of filament would probably be ruined if I left it outside the dry box, but I have had a few rolls of PLA I stored in a heated/controlled cabinet (~35% humidity) and when I wanted to use it again I didn’t see any issues. The placement of the dry box is a problem for some but I have 360 degree access to the printer in the garage so that hasn’t been an issue, although side mounts exist for the box if you wish to move it.

Print quality is superb. Some materials will be touchy (ASA has been functional but not perfect for me, which is fine since I’m replacing outdoor fixtures for plumbing/ducting) but once you calibrate your filament, keep up on maintenance, and keep an eye on your first few layers you will find there are thousands of settings and variables you can change to adjust the print quality. I’ve been printing anything from statues/models to pots, functional items for outdoors, dryer ducting, and parts to enhance my existing tools like my dremel and reloader. The library of models available is huge now which is great, but I have recently been trying to model my own items since I have a CAD license for work and there are just some items you can’t find.

The volume of the printer sold me and has been great for printing pots for our large garden, or just large items in general. Gluing parts together isn’t the worst thing but if I can print something large as a single item it’s much less of a headache. Multi-material or color feeds would be great but I don’t care much as if I want something cosmetic I will spraypaint or paint with acrylics. Any problems I’ve had will be found in any printer and I don’t blame the hardware for issues. I’m not an expert and can’t speak much on the software but I know they use a hard forked custom version of klipper/moonraker. I’m assuming their PCB’s are programmed around that and updating might be very labor intense. If you want to you can erase their firmware and use custom firmware on the machine but I don’t see any reason to. Also NEVER update klipper or moonraker in the fluidd interface. As I said they have a custom version and you cannot undo an update. I tried for days but eventually support helped me find a new eMMC with the correct firmware installed and a tool for connecting it to your computer for backup/reflashing if anything goes wrong again.

Overall, great support, great features, not too hard to learn for someone with 0 experience in this hobby and the issues can usually be fixed. The possibilities are endless and the capability of this printer in particular is great. I plan to use it to print automotive parts, UV and weather resistant items, and many other advanced materials since it has a high heat build plate and a heated enclosed chamber. I wish they would gain a bigger following and be able to grow since I can tell the company wants to succeed and are very responsive to customer feedback. I look forward to continue using the printer and contributing to the knowledge base to help the company grow and improve.

Anthony A. –

The Qidi Max3 has been a great addition to my 3D printers. This is the dearest one I have purchased but its capabilities justify the price. This is the first printer that I have had no issues printing with ABS. Other printers can do it but the heated chamber on this printer takes it from a 50/50 to almost 100% success.

I had an issue this the printer, followed the instructions, and QIDI got back to me within 2 days with a solution. They sent out the required items to fix the issue and included easy-to-follow videos on how to install the fix.

Great to see a 3D printer company that supports its customers so well.

Anthony A. –

I am one of those believing that in order to make useful models you need as large as possible and enclosed 3D printer. This is my forth 3D printer, having two of the older Creality (Ender 3 and 5Plus ) and the BambuLab X1C . While the Ender 5 Plus has a slightly bigger bed, Qidi XMax3 is way more faster (and much bigger than BambuLab). At this size and speed, the prints quality came very good. The little things that I needed to improve on my Qidi , they were a breeze with the very prompt and meaningful help from Annie and Alice from Qidi Tec. I will probably buy the next Qidi upgraded printer model also.